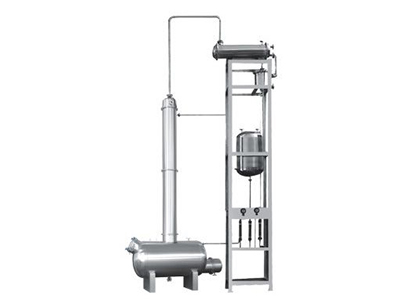

Auxiliary Equipment

At Weiying, we pride ourselves in our ability to produce stainless steel tanks and pressure vessels for a diverse range of industries, such as pharmaceutical, food, chemical, light industry and other industries. Our stainless steel pressure tanks are built according to the rigorous industry standards, ensuring every tank we manufacture is dependable and long-lasting. In order to provide the stainless steel tank that is both cost-effective and safe, our team of engineers takes into account the factors in terms of internal pressure, working temperature, wind and seismic loads, corrosion allowance and other conditions.

To learn more about our quality, please view our assortment of stainless steel tanks such as multifunctional extracting tank, alcohol rectification column, stainless steel liquid dosing tank, stainless steel fermentation tank, alcohol deposition tank, reaction vessel / crystallization tank, stainless steel jacketed tank, tubular heat exchanger, CIP cleaning system, etc.

Discover more about features of our auxiliary equipment:

Stainless steel extracting tanks for the extraction of desired substances from various materials

Inner body of the tank is manufactured from 316L stainless steel or 304 stainless steel. It adopts internationally accepted ISO standard quick-fit chuck

The tank is equipped with automatic high-pressure water spraying and rinsing system, and low-temperature cooling water can be passed through the jacket

Used to mix a certain volume of two (or more) liquids with solids or liquids with the help of an agitator at specific/moderate pressure and temperature, so as to generate spontaneous chemical reactions

Used in a variety of industries with high cleaning requirements, in order to achieve optimum results in hygienic and aseptic technologies

Commonly used in pharmaceutical, food, chemical, light industry and other industries for decoction and concentration of liquid

Extensively used in the pharmaceutical industry for liquid or gas heating, cooling and evaporation

A sealed heat exchanger with different specifications of tubes, conforming to GMP requirements