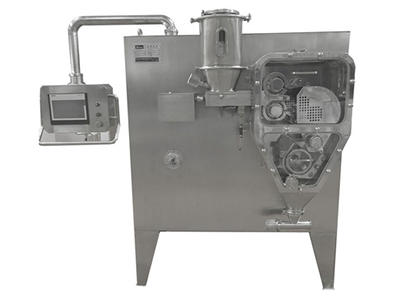

- Tank material: stainless steel S31603 or S30408

- Tank design pressure: 0.3MPa

- Jacket design pressure: 0.35MPa

- Tank structure: fermentation tank (sampling), discharging valve, standard temperature/PH/DO sensor socket

- Tank lid structure: 1 foam electrode socket, 1 light mirror, 3 common charging inlets, 1 air vent

- Surface treatment: stainless steel internal and external polishing to mirror finish, polishing accuracy Ra0.4

- In-situ steam sterilization;

- Standard type blades are specially used for fermentation

- Control range: 50-300rpm

- Control accuracy: ± 1%

- Cooling water temperature: +5~65℃

- Temperature control accuracy: ±0.1℃

- Mettler Toledo pH electrodes and shielded cables

- pH range: 2~12pH

- pH control accuracy: ±0.02pH

- Mettler Toledo DO electrodes and shielded cables

- Range: 5~100%

- Control accuracy: ±2%

- Automatic detection of foam to add defoamer

- Sensitivity 100-100000

- Automatic peristaltic pump

- Range: 0-5L / min,

- Control accuracy; ± 2%

- Manually operated adjustment

- Range: 0-5000L/min

- Stirring method: standard mechanical agitation system

- Nominal capacity: 100L~50000L;

- Height to diameter ratio: H: D=2.0-3.0;

- Charging factor: 0.7;

- Sterilization form: in-situ sterilization;

- System configuration: general three-tiered fermentation;

- System parameter control: three-tiered fermentation control is available, which is individually adapted to the customer’s needs;

- Auxiliary system: seed tank, fermentation tank, control system, air filtration system, pipes and valves, utilities, etc.;

| Model | ||||||||

| Diameter (mm) | 400 | 500 | 700 | 900 | 1200 | 1500 | 5250 | 6550 |

| Height (mm) | 2000 | 2300 | 2650 | 2900 | 3800 | 4480 | 5250 | 6550 |

| Numbers of agitators | 1 | 1 | 2 | 3 | 3 | 4 | 4 | 4 |

| Agitator speed (r/min) | 20-300 | |||||||

| Motor power (kW) | 0.55 | 0.75 | 1.1 | 1.5 | 3 | 5.5 | 7.5 | 7.5 |

| Jacket pressure (MPa) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Inner working pressure (MPa) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

If you have questions about our products or want to request a quotation, please feel free to contact us at any time.