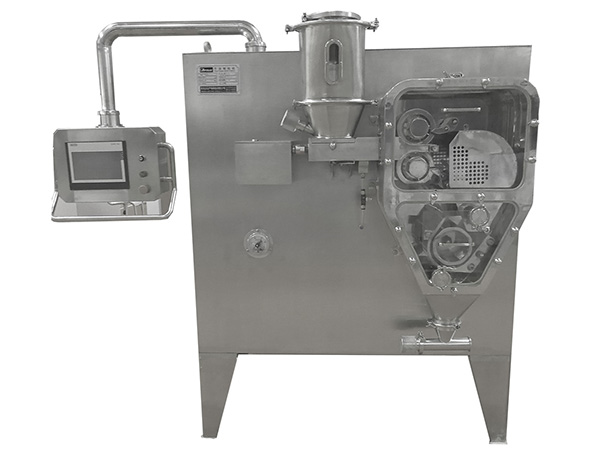

- Dry powder particles manufactured with the GK series dry granulator are of uniform and even density, good solubility and high granulation rate;

- Special feeding structure of this dry granulator ensures effective feeding;

- The water circulation cooling of the rollers is used to avoid material sticking to the roller;

- No need for moisturizing agent such as water or ethanol, no need for secondary heating and drying process;

- The dry granulator adopts cutting-edge electronic hydraulic control (EHC) technology, resulting in higher work efficiency and lower cost;

- The sealed operation process is pollution-free, thus complying with sanitary and hygiene requirements;

- This dry granulator is particularly applicable for granulation of materials that cannot be manufactured with wet granulation method;

| Model | |||||

| Producing capacity (kg/h) | 10--30 | 30--100 | 40--120 | 50--200 | 100--300 |

| Hopper capacity (L) | 3 | 5 | 7 | 10 | 15 |

| Roll width (mm) | 50 | 100 | 120 | 200 | 280 |

| Roll pressure (MPa) | 0--7 | 0--7 | 0--7 | 0--7 | 0--7 |

| Roll speed | 1-60r/min (Variable-frequency and speed-adjusting VVVF) | ||||

| Feeding speed | 1-80r/min (Variable-frequency and speed-adjusting VVVF) | ||||

| Drive motor for roller (kW) | 3 | 7. | 11 | 13.5 | 32.7 |

| Drive motor for feeding (kW) | 1.1 | 2.2 | 2.2 | 3 | 3 |

| Drive motor for granulation (kW) | 1.1 | 2.2 | 2.2 | 3 | 7.5 |

| Drive motor for lube pump (kW) | 0.75 | 1.1 | 1.1 | 2.2 | 2.2 |

| Dimension (L×W×H) (mm) | 1.2×0.7×1.7 | 1.8×1.2×2.1 | 1.8×1.3×2.2 | 2.1×1.5×2.3 | 2.2×1.8×2.5 |

| Weight (T) | 1 | 1.5 | 2 | 2 | 3 |

Note: Due to material difference, the output in the table is for reference only.

If you have questions about our products or want to request a quotation, please feel free to contact us at any time.